steaming provides a natural wood colour

Series COPCAL VAP

Wood steaming chambers.

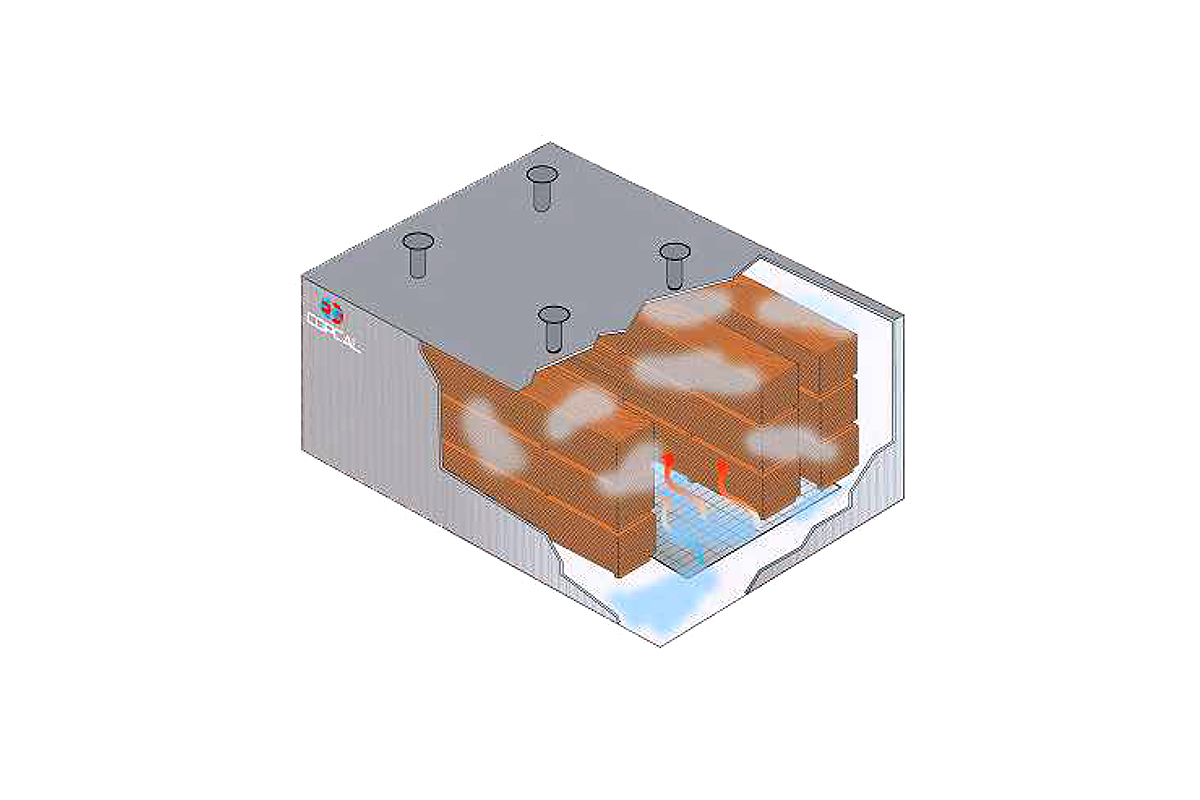

Units with a direct or indirect vaporization system where the action of the steam together with the air temperature at +90°C, melts the minerals and sugars of the wood changing its natural colour and making it uniform.

The steaming process makes the wood tougher, longer-lasting and more stable. It also gives it a pleasant warm hue that tends to pinkish-brown.

Versions available:i:

- COPCAL VAP-D Direct steam; the steam required is produced by a generator and is injected via special pipes to the chamber, while the condensate is collected and removed via ducts integrated in the base of the chamber.

- COPCAL VAP-I Indirect steam; the required steam is made by a tank incorporated in the base of the chamber, which, once filled with water is heated by a heat exchanger fed with overheated water, steam or diathermic oil or with indirect heating by means of water/fume exchangers fed directly by a gas generator. The condensate is collected inside the tank.

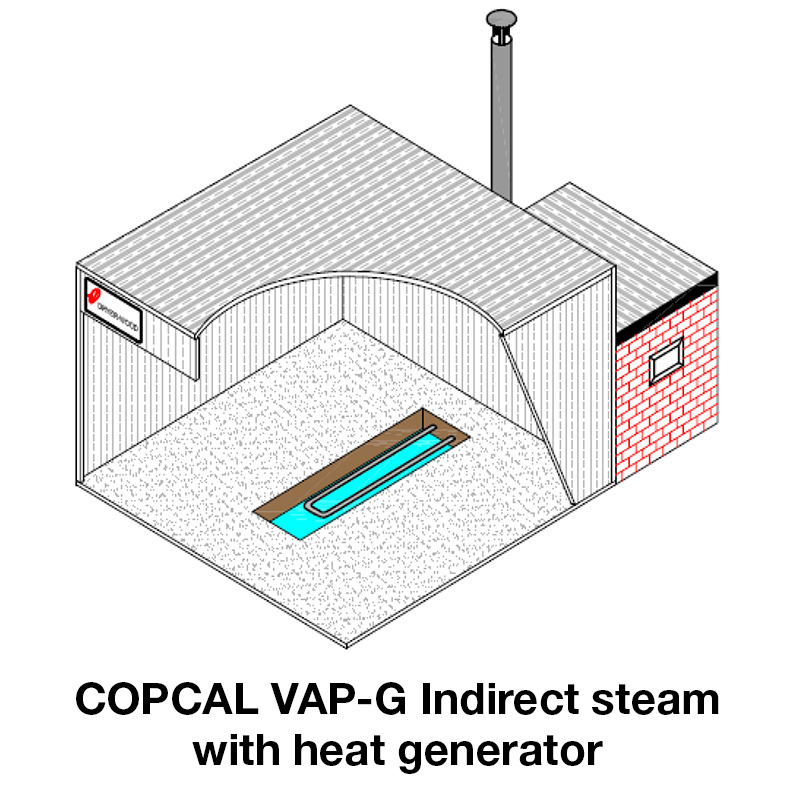

- COPCAL VAP-G Indirect steam with heat generator; the steam required for the vaporisation process is produced by a tank on the base of the chamber with water/fume exchangers fed directly by a gas or diesel generator. The condensate is collected inside the tank.

- Loading capacity from 10 to 100 m3 per vaporisation cycle;

- Prefabricated load-bearing structure in AISI/304 stainless steel, or alternatively in masonry, constructed by the client;

- High density mineral wool head insulation;

- Loading system with front fork lift truck or trolleys on rails;

- Dryer Wood automatic process control;

- Large hinged or sliding doors.